In November 2021, the IEA reported an increase of 144 TWh (+11%) in onshore wind capacity and 25 TWh (+29%) of growth offshore.

The full impact of this construction boom on electricity generation will be most visible in 2022.

Now is the time for generators and asset owners to start thinking smartly.

And as O&M risks are constantly changing, should we adopt a traditional one-dimensional approach to managing them?

If NO is your answer, you are absolutely right.

But then, what influences those changes? The answer is … the nature of the work activities themselves.

In the renewable industry, there are several examples of risk profiles that you will encounter. These include:

- Asset design risks

- Operations and maintenance (O&M) risks

- Major component change risks

- Construction or re-powering risks

- Warranty to post-warranty transition risks

- Contractor risks

- Vessel management risks

In this post, we will examine Operations and Maintenance risk profiles with a particular focus on the impacts of preventative and breakdown maintenance on risk.

O&M risk profile

High performing renewable businesses recognise that their risk profiles are unique. What makes them unique are:-

- Nature of its activities

- Asset design and technology deployed

- Contracting arrangements and incentives such as warranties and performance bonuses

- Work management within the service team; across contractors and sub-contractors

- Existing risk management tactics inhereted from pre-commissioning and testing phases. These could include retained risks, reduced (shared) risks, controlled and transferred risks.

Risk profiling is the starting point for determining the greatest health and safety issues for the organisation. It examines:

- the nature and level of the threats faced by an organisation

- the likelihood of adverse effects occurring

- the level of disruption and costs associated with each type of risk

- the effectiveness of controls in place to manage those risks

Effective risk profiling produces a reliable and prioritised risk inventory. And it also informs decisions about risk control measures needed.

Let’s now look at the composition of Operations and Maintenance risks.

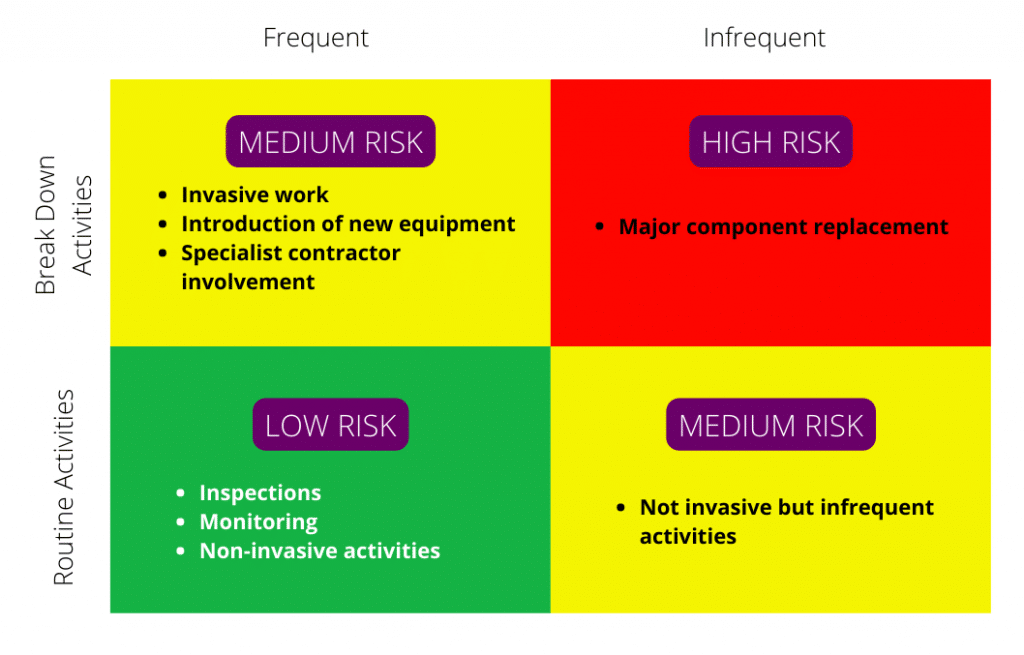

We can classify operations and maintenance activities into routine and non-routine (or breakdown).

These, in turn, can be frequent or infrequent activities. The nature and frequency of these activities result in varying levels of inherent task risk.

Risk Matrix

As you can see from the risk matrix, frequent routine activities such as inspection, monitoring, and other non-invasive activities are inherently low risk. Examples include visual inspections, thermographic monitoring, oil sampling and SCADA inspections.

Why? Routine activities are performed frequently, often by the same teams, who are very familiar with the work environment and task. Also, these activities are inherently safer because there is little to no invasion with the asset and its structures.

In contrast, breakdown / unplanned repair activities that are infrequent, such as major component repair or replacement campaigns will have high inherent task risk. Examples include bearing changes, gearbox changes, blade repairs or replacement.

Frequent breakdown activities are classified as medium-risk due to their invasive but frequent nature, therefore these activities will be familiar to technicians using verified repair methods.

Examples could include yaw motor swap-outs, crane repairs, nacelle repairs, lift repairs and so on. Similarly, infrequent routine activities will also be classed as medium-risk.

Although activities are routine since they are infrequent, changes to people, work environment and task process in between these activities taking place are likely.

O&M activity risk profile pattern

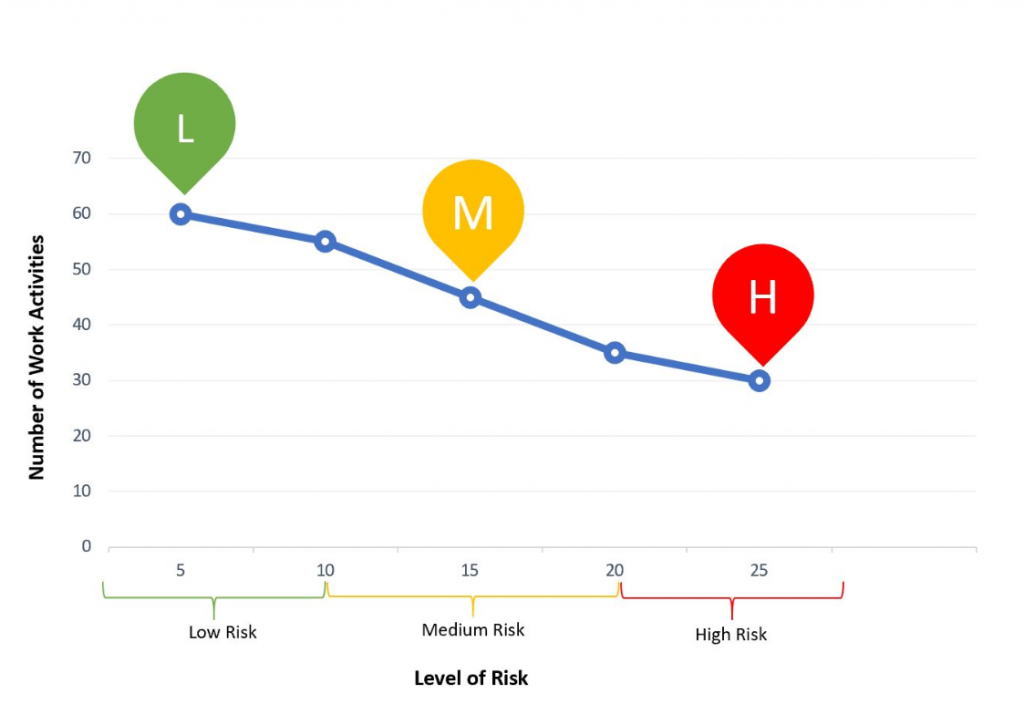

When we look at the low/medium/high-risk ratio, what type of pattern do we want?

The graph shows an ideal pattern with a high volume of low-risk, followed by a medium volume of medium risk activities. A low volume of high-risk activities is what we are seeking.

This is a powerful risk profiling tool. Not only will you be able to predict the chances of an accident occurring, but it is also an indicator of asset health.

If the actual trend is anything different to the above, then it shows both an operational and safety problem. Insufficient planned preventative maintenance leads to increased breakdowns and reduced time between failures.

Dealing with inherent High / Medium / Low risk groups

Low-risk activities will benefit from a baseline risk assessment and a standardised safe work procedure. Only significant changes in the process will require a review of controls.

Medium-risk activities require a set of RAMS that must be reviewed in the planning phase of each activity. And involving both the authorised engineer and the lead technician will produce a realistic view of the controls.

High-risk activities must be supported by a HAZOP involving all parties in the design stage activity. The scope of work requires close examination and should be locked down as early as possible.

This approach ensures plant availability means that more people will be rapidly deployed to the assets to resolve unplanned breakdowns.

Points to remember

So, what are the points to remember?

- The risk level across all your O&M activities will vary depending on the type of activities that take place.

- The volume of routine and non-routine work are critical factors in determining your O&M risk profile.

- Remember, that dealing with unplanned breakdowns is always a lot riskier than planned routine and non-routine activities – and should always be approached with extra caution.

- Preventative maintenance is always a lot safer than breakdown maintenance.

- And finally, your ideal O&M risk profile should constitute of a large number of low-risk activities, and low number of high-risk activities.

To learn more about how our performance support sprints can guide mission-critical individual and collective decision-making, follow us and sign up to our Newsbyte below.

If you are an O&M manager, this Performance Support journey is relevant to you.

Already on the platform? Sign in here

What does world class risk based O&M look like? © 2021 by Khalida Suleymanova – ARMSA is licensed under CC BY-NC-ND 4.0