Who is it for?

Onshore and offshore wind power professionals, including:

- Operations managers

- Maintenance managers

- O&M package managers

- Operations and maintenance engineers

- Service planning managers

- Deputy O&M managers

What will you gain?

You will refine critical decision-making skills, including:

- A range of work planning and execution decisions

- Insights on optimising safe, effective and efficient management of sites

- How to improve processes and achieve safety excellence

- When and how to successfully collaborate with other departments

- The best ways to effectively and safely set people to work

Ultimate performance support

- 10 hours of bite-sized self-paced learning sprints

- Access to video materials and downloadable transcripts

- 24/7 access to digital resources

- Available on desktop and on the go with the mobile app

- Engage with a community of industry experts

- CPD certificate

How good is this solution?

Performance support helps:

- Cut frictional costs by 5%

- Reduce scope variations by 10%

- Proactively identify asset and occupational health and safety risks and opportunities

- Easily accessible via the app whilst you work

- CPD UK approved

Is performance support for you?

Is encouraging your people to work collaboratively whilst constantly improving processes and safety a challenge?

It is for most O&M Managers! Whether you manage a local site or are responsible for an extensive portfolio spanning many countries, ARMSA Academy’s performance support sprints equip you with the insights and knowledge you need to make better-informed decisions.

Available online and on the go, our portfolio of circa 40 short video-based materials is at your fingertips so you can inform, verify, and improve decisions whenever and wherever.

We help you succeed in your role. With performance support by your side, you develop more confidence in making informed decisions whilst navigating O&M milestones.

Performance support maximises production, helps you proactively manage risk and pinpoint performance improvements. The solution helps better decision-making in the workflow, and we also connect you with a global community of like-minded professionals for insightful peer opinion.

Curious to learn more? Try the free demo!

But don’t just take our word for it.

Hundreds of leading wind energy organisations worldwide trust the ARMSA approach.

Trusted By

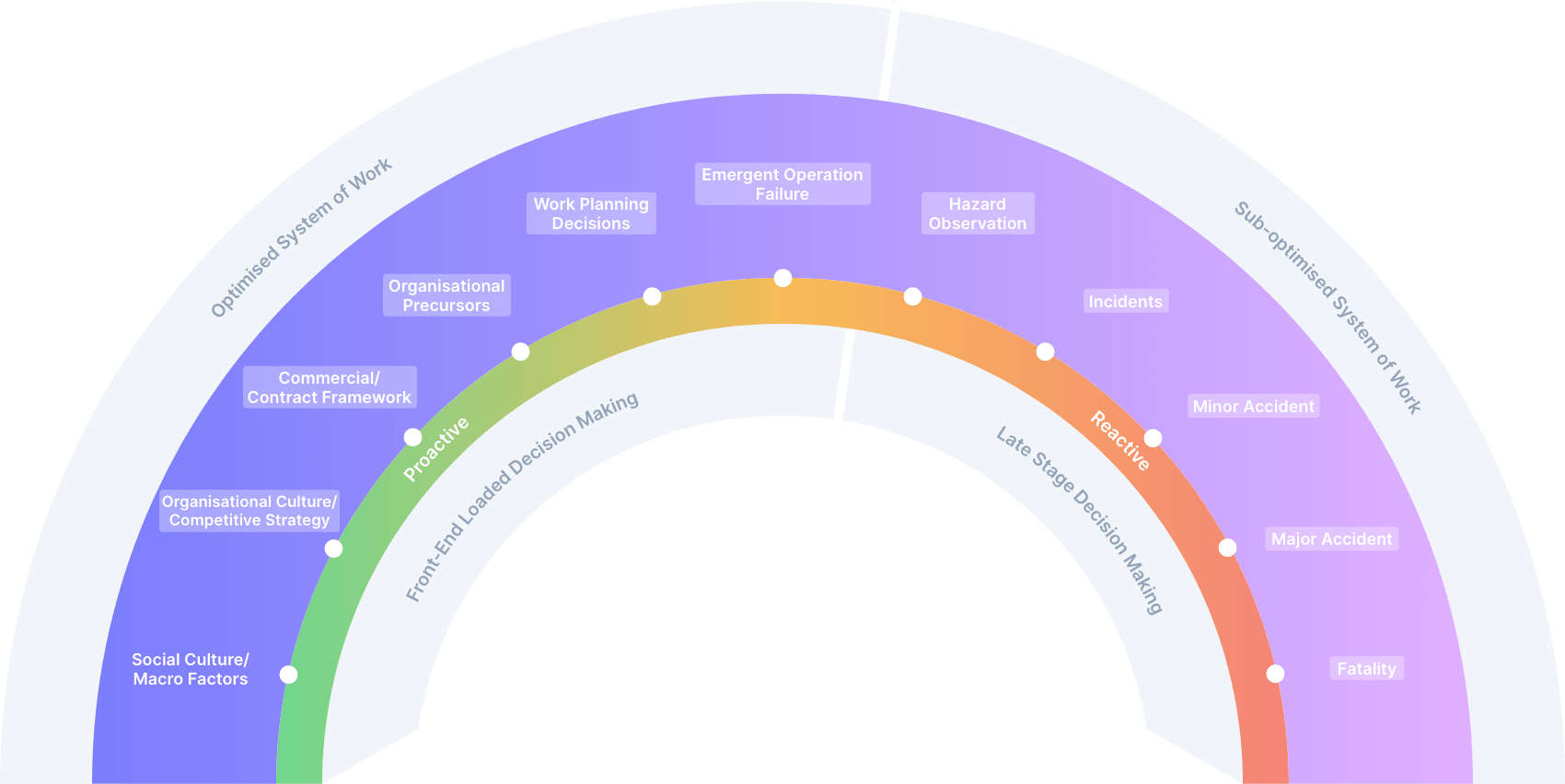

Our approach

Front-end decision-making components

- Organisational culture

- Commercial/contract framework

- Organisational precursors

- Work planning decisions

- Emergent operations failure

Late-stage decision-making components

- Hazard observation

- Incidents

- Minor accident

- Major accident

- Fatality

Performance support aims

How often are your decisions rushed, constrained by time, cost or because you didn’t have anyone to bounce your ideas off?

Performance support helps you do things right, right from the start. Learn to understand the consequences of your decisions and make choices that result in safer, more effective, and more efficient outcomes.

Our performance support content is built around the cycle:

- Leadership

- Plan

- Do

- Check

- Act

Decision-making content

The performance support portal comprises circa 40 short video sprints supported by written transcripts. Each video can be viewed in any order and as many times as you like.

Search for the content you need advice for, and the platform will generate suggestions for you to consider.

The videos cover the critical decision-making points of each phase:

Master your leadership

- What effect is your management style having in practice?

- Leadership styles – which one is right for you?

What should be considered in the planning phase?

- Operationalising the risk assessment process

- The impact of technical specifications on risk

- The effect of contracting strategies on risk

- Planning for emergencies: are you covering all the scenarios?

- The impacts of preventative and breakdown maintenance on risk

- What is competence?

- Growing your portfolio: what is organisational change?

- The importance of job risk profiling when hiring staff

- The wider benefits of management of change

- Basics of applying construction safety regulation to operations and maintenance

- Scheduled maintenance strategy – what are the options?

- The practical use of principles of prevention

Enhancing performance (Do)

- The relationship between safety rules, risk assessments and work instructions

- Practical application of Permit to Work

- The relationship between work instructions, risk assessment and method statements

- Reviewing risk assessments: improving operational control and reducing liability

- Setting people to work effectively.

- Safe, effective and efficient delivery of work – a work management approach

- Planning and organising for work

- How to use RAMS to streamline O&M procedures?

- What are the components of a standard operating procedure (AWP v RAMS)?

- Do you have a robust enough Emergency Response organisation?

- What to do if an HSE inspector calls?

- Effective hazard identification.

Monitoring performance (Check)

- Inspections and audits: is there a difference

- Supervision and monitoring – is there a difference?

- Comparing methods for investigating accidents and incidents

- Leading and lagging indicators for safety

- Choosing the right team for investigating accidents and incidents

- The criticality of statutory inspections

- Finding the true leading KPIs

- Developing audit questions to do the right things right, not more of the wrong things right.

- Using cause and effect to identify plant/contract-specific KPIs

- A practical approach to risk-based monitoring

Learning lessons (Act)

- Common pitfalls of the setting people to work process

- Common pitfalls associated with risk assessments

About the Facilitator

Send me a brochure

Simply enter your email and we’ll send a copy of the course brochure straight to your inbox.

You may also be interested in

Reviews

There are no reviews yet.